On June 1, researchers at Virginia Tech published a breakthrough study in Advanced Materials, unveiling a new class of printed circuit boards (PCBs) that are self-healing, reconfigurable, and fully recyclable. Designed to address the growing global challenge of electronic waste, the innovation leverages a novel combination of liquid metal and vitrimer—a dynamic polymer that can change shape and be repaired with heat.

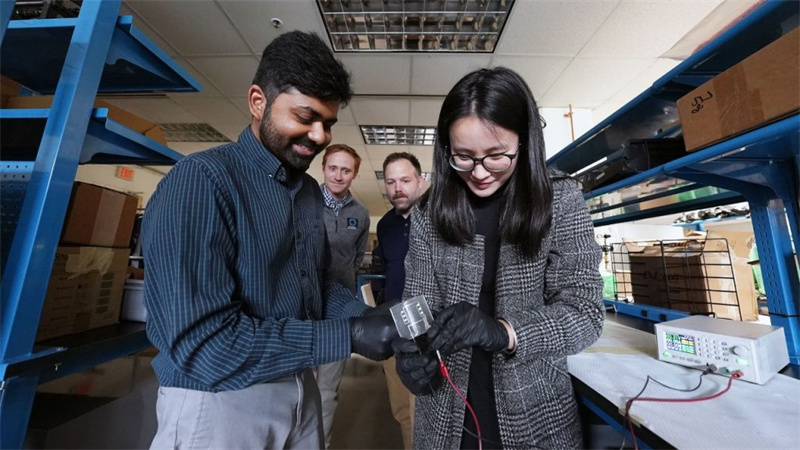

The research, led by mechanical engineering associate professor Michael Bartlett and chemistry assistant professor Josh Worch, introduces a PCB material that retains the mechanical strength of traditional circuit boards while gaining remarkable adaptability. Unlike conventional thermoset-based PCBs made from rigid, non-recyclable materials like epoxy or silicone resins, the new vitrimer-based boards can be reshaped or repaired simply by reheating—without compromising electrical performance.

“Our material is unlike conventional electronic composites,” said Bartlett. “The circuit boards are remarkably resilient and functional. Even under mechanical deformation or damage, they still work.”

The circuit design blends vitrimer with just 5% liquid metal droplets, which replicate the conductive function of rigid wires in traditional boards. This unique combination provides not only high conductivity but also flexibility, durability, and ease of disassembly.

Traditional circuit boards, once damaged or outdated, typically require complex, energy-intensive recycling processes that recover only a small fraction of materials—often sending the rest to landfills. In contrast, the new PCBs can be broken down via alkaline hydrolysis to reclaim components like LEDs and liquid metal, offering a clear path toward closed-loop reuse.

“Traditional circuit boards are made from permanent thermosets that are incredibly difficult to recycle,” Worch explained. “Here, our dynamic composite material can be healed or reshaped if damaged by applying heat, and the electrical performance will not suffer. Modern circuit boards simply cannot do this.”

The innovation arrives at a time of mounting concern over electronic waste. According to a 2024 United Nations report, global e-waste has nearly doubled in the past 12 years—from 34 billion to 62 billion kilograms—with only 20% expected to be recycled. That number is projected to remain stagnant through the end of the decade.

Backed by Virginia Tech's Institute for Critical Technology and Applied Science and a National Science Foundation CAREER award, the study highlights a promising step toward circular electronics. The researchers aim to further improve material recovery rates and adapt the technology for use in everyday devices—from smartphones and wearables to industrial and defense systems.

+86 191 9627 2716

+86 181 7379 0595

8:30 a.m. to 5:30 p.m., Monday to Friday