SK Hynix, a global memory leader, and LG Innotek, a latecomer but fast-rising player in semiconductor substrates, are exploring potential collaboration in flip-chip ball grid array (FC-BGA) technology. The move could signal a shift in South Korea's semiconductor supply chain, which is under pressure from both soaring AI-driven demand and global supply uncertainties.

Industry sources said the two companies recently held a technology exchange meeting at LG Science Park in Seoul, with SK Hynix's packaging design division and LG Innotek representatives in attendance. The discussion, initiated by LG Innotek, focused on cooperation opportunities in FC-BGA substrates, a critical packaging component that connects memory chips to mainboards.

FC-BGA is considered one of the most advanced semiconductor substrates due to its high circuit density and reliability, yet global suppliers remain limited. SK Hynix currently sources FC-BGA substrates from Japanese and Taiwanese companies and does not transact with domestic players such as Samsung Electro-Mechanics or LG Innotek. However, with demand for AI memory surging and supply chain risks rising, collaboration with local partners is increasingly seen as a strategic option.

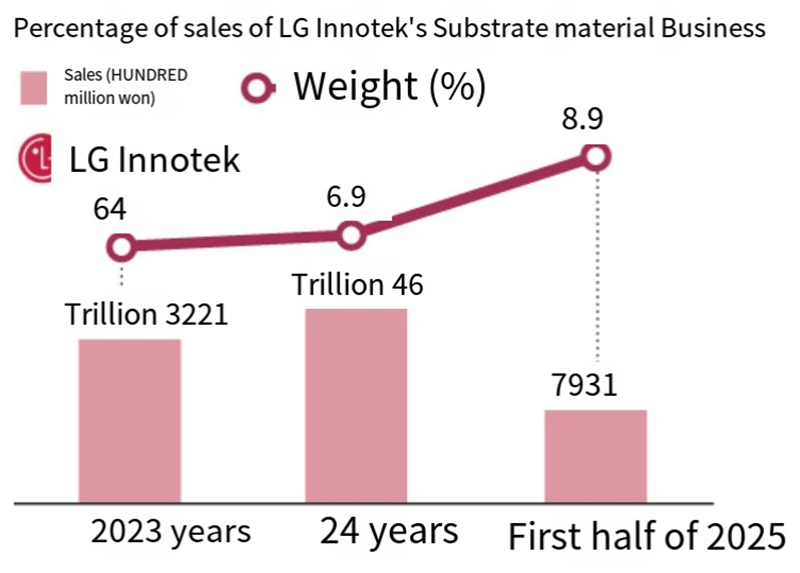

LG Innotek entered FC-BGA mass production in early 2023, leveraging decades of experience in high-density telecom substrates. The company aims to scale its FC-BGA business into a multitrillion-won segment by 2030, expanding beyond its camera module core business, which still accounts for about 80% of sales. Its advanced "copper post" technology, which boosts substrate efficiency and reduces size by up to 20%, has drawn particular industry attention.

Market observers note that as AI semiconductors diversify, memory makers like SK Hynix will benefit from building closer ties with multiple substrate suppliers to secure stable and flexible supply chains.

+86 191 9627 2716

+86 181 7379 0595

8:30 a.m. to 5:30 p.m., Monday to Friday