A Global Leader in PCB and IC Substrate Equipment and Solutions, SCHMID Group (NASDAQ: SHMD) announced on December 2 the successful delivery and installation of its first InfinityLine C+ system for a major Japanese customer in the advanced packaging and high-end substrate market.

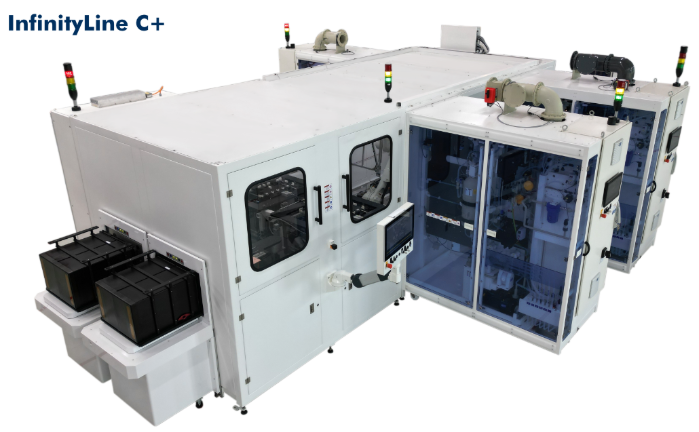

The InfinityLine C+ is SCHMID's next-generation vertical spin-process platform, engineered to deliver industry-leading uniformity, touch-free single-panel processing, and fully automated panel handling. The installation marks a significant milestone for SCHMID as it expands its leadership in Panel Level Packaging (PLP) and high-density glass substrate manufacturing, strengthening its presence in one of the world's most dynamic electronics markets.

Expanding Into AI Server PCB Applications

It is worth noting that on October 22, SCHMID Group announced the successful acquisition of two significant orders in the fast-growing field of PCB for artificial intelligence (AI) server applications, commonly referred to as AI-Server-Boards. In one project, SCHMID will deliver a complete wet-process equipment setup featuring its advanced V+ and H+ systems. The second project involves the supply of technically critical horizontal H+ machines, representing a breakthrough beyond the company’s traditional PCB and IC-substrate business. These wins highlight SCHMID's growing presence in next-generation PCB markets and its ability to meet highly specialized customer needs.

A New Standard in Wet Chemical Processing

Developed as a modular, vertical, touch-free cluster tool, the InfinityLine C+ supports a broad spectrum of critical wet processes essential for high-density interconnect (HDI) and advanced substrate production. Its tightly integrated architecture minimizes manual handling, enhances yield stability, and enables rapid recipe changes for flexible, high-volume manufacturing environments.

Technical Highlights and Key Benefits

Touch-free vertical single-panel processing for maximum yield and minimal contamination

Full automation with FOUP/OHT integration and SCHMID's MCF logistics system

Highly uniform etching and developing for advanced line-space requirements down to 2 μm

Optimized wet-chemical architecture ensuring tight process windows for copper and titanium flash etch

Efficient wet-film stripping utilizing environmentally friendly DMSO chemistry

Scalable modular cluster design compatible with SCHMID's InfinityLine H+, V+, and P+ systems

Reduced footprint and lowered labor requirements enabled by vertical automation

Collectively, these capabilities provide higher uptime, stable throughput, and lower total cost of ownership for manufacturers producing next-generation substrates and PLP architectures.

Executive Statement

"The successful installation of our InfinityLine C+ is a significant milestone and a strong validation of our wet-process strategy," said Roland Rettenmeier, CSO of SCHMID Group. "The C+ brings together high-precision developing, selective flash etching, and efficient wet-film stripping in a fully automated, touch-free platform designed specifically for next-generation glass and substrate manufacturing. This system will support our customer in Japan as they advance next-generation Panel-Level Packaging technologies.

"What truly differentiates the InfinityLine C+ is its seamless logistics integration, vertical single-panel handling, and its ability to consistently achieve 2-micrometer line-space performance. These strengths make the C+ a highly competitive solution for manufacturers requiring uncompromising uniformity, flexibility, and yield.

"We are proud to provide a system that not only meets today's advanced packaging requirements but also establishes a scalable foundation for future technology generations."

Outlook and Availability

With the successful shipment and installation of the first system, SCHMID has entered the commercialization phase for the InfinityLine C+. Customer demonstrations, system integrations, and volume-production configurations are now available.

The InfinityLine C+ enhances SCHMID's advanced wet-process portfolio and complements the InfinityLine P+, H+, and V+ platforms, offering a complete and modular ecosystem for substrate and PLP manufacturing.

About The SCHMID Group

The SCHMID Group is a global leader in high-tech solutions for the electronics, photovoltaics, glass, and energy-systems industries. Headquartered in Freudenstadt, Germany, the company was founded in 1864 and employs more than 800 people worldwide. SCHMID operates technology centers and production facilities in Germany, China, and several additional international locations. Its systems and process solutions for substrates, printed circuit boards, and electronic components focus on achieving cutting-edge performance with high yields, low production costs, and sustainable, environmentally friendly manufacturing processes.

+86 191 9627 2716

+86 181 7379 0595

8:30 a.m. to 5:30 p.m., Monday to Friday