At SEMICON Japan 2025, held from December 17 to December 19 at Tokyo Big Sight, advanced Japanese PCB manufacturer FICT and Osaka-based stretchable PCB specialist Satosen Co., Ltd. unveiled next-generation circuit board technologies targeting advanced semiconductor packaging, wearables, and emerging electronics applications.

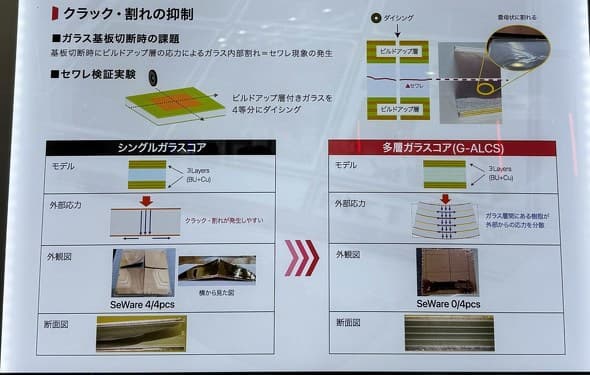

During the exhibition, advanced FICT presented its glass core substrate technology known as G-ALCS (Glass All-Layer Z-connection Structure) for next-generation semiconductor packages. The company explained that G-ALCS is formed by laminating multiple thin glass substrates with resin and electrically connecting them using conductive paste. When used as the core layer of a build-up substrate, the structure significantly reduces warpage and suppresses internal glass cracking, known in Japanese manufacturing as "seware."

According to FICT, unlike conventional organic substrates that exhibit severe warpage at high temperatures, G-ALCS remains almost flat even at approximately 250 degrees Celsius, making it well suited for reflow processes. The structure also demonstrates strong resistance to glass cracking during dicing. At the exhibition, FICT displayed samples in which glass substrates with build-up layers were diced into four sections. While samples using a single glass core showed clear internal cracking from the center, the G-ALCS samples exhibited no cracking at all, as the resin layers between glass sheets absorbed and dispersed stress.

FICT also highlighted productivity advantages, noting that multiple glass substrates can be processed in parallel. If a defect is found, only the affected glass layer needs to be replaced, rather than scrapping the entire core. In addition, the thickness of each glass layer can be customized depending on function, with thinner glass for signal transmission and thicker layers for power delivery. The company emphasized that both the resin and conductive paste are proprietary materials developed in-house, along with a dedicated manufacturing process that competitors would find difficult to replicate.

On December 18, 2025, FICT announced the establishment of new research and development centers to accelerate the development of three-dimensional multilayer interconnect technologies. The new facilities will be located in Nagano City, Kawasaki City, and Itoshima City. These sites will also be equipped with G-ALCS manufacturing capabilities, with sample production targeted to begin in June 2027.

Alongside FICT's glass substrate technology, advanced Satosen Co., Ltd., a developer and manufacturer of stretchable printed circuit boards, demonstrated its latest high-durability stretchable PCB solutions. At the booth, visitors were able to physically experience repeated stretching demonstrations showcasing the flexibility and robustness of the boards.

Stretchable LED circuit board (example)

Satosen explained that its stretchable PCBs go beyond conventional flexible circuits by combining extreme elasticity with long-term durability, making them suitable for wearable devices, stretchable displays, and soft robotics. A key highlight was a high-durability stretchable PCB capable of withstanding more than 250,000 stretch cycles while maintaining electrical continuity. The breakthrough was achieved by applying the company's liquid metal wiring technology—commercially introduced last year—to stretchable circuit structures, overcoming the conductivity degradation commonly seen in traditional metal paste wiring.

Company engineers were present on-site to provide technical explanations, and exhibition-only samples were made available to visitors, allowing hands-on evaluation of the stretchable PCB technology.

+86 191 9627 2716

+86 181 7379 0595

8:30 a.m. to 5:30 p.m., Monday to Friday