April 13, 2025, Pat Gelsinger, the former CEO of Intel, has joined xLight as its Executive Chairman, the company announced in a LinkedIn post. The news was also shared on the xLight official website last month.

xLight is a startup focused on developing Free Electron Laser (FEL) technology to create an Extreme Ultraviolet (EUV) light source for semiconductor manufacturing. The company claims that its EUV-FEL system could reduce both system and operational costs by a factor of three, with commercial applications expected to be ready by 2028. Furthermore, the new system is designed to be compatible with existing EUV equipment.

In his LinkedIn post, Gelsinger emphasized, “We are entering one of the most transformative periods in computing infrastructure since the advent of the internet. I look forward to working with xLight to advance the next generation of semiconductor manufacturing. Free Electron Lasers (FEL) represent the future of lithography, and xLight is undoubtedly a leader in the field of particle accelerator technology.”

Nicholas Kelez, CEO of xLight, added, “Pat shares our belief that EUV lithography is the key to unlocking the next generation of computing. When he learned of the work xLight is doing to build the world's most powerful laser and revolutionize EUV technology, it was an instant match. His deep understanding of semiconductor technologies and his vision for the future of the U.S. semiconductor industry make him an invaluable addition to our board.”

The Advantage of EUV-FEL

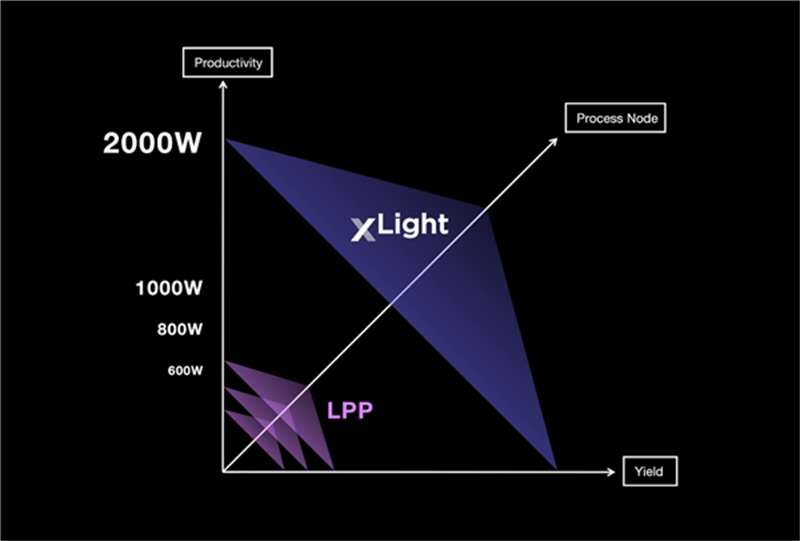

Current EUV lithography machines, such as those from ASML, use a laser-plasma EUV light source (LPP). This process involves firing a powerful CO2 laser at tin droplets, vaporizing them to generate EUV light at a wavelength of 13.5 nm. While effective, this method is costly and power-hungry, requiring significant energy to produce limited EUV light power. Consequently, only a handful of leading semiconductor manufacturers can afford these €150 million machines, primarily used for advanced chip manufacturing below 7 nm nodes.

Researchers in the U.S., China, and Japan have been exploring alternative EUV light sources based on FEL technology, bypassing the laser-plasma approach. The FEL method, particularly the Self-Amplified Spontaneous Emission (SASE) FEL, offers a promising solution by using a linear electron accelerator to generate high-power EUV light without the need for the energy-intensive laser pulses that characterize LPP sources.

FEL-based EUV sources offer several advantages over LPP. They can produce EUV power exceeding 10 kW and can serve multiple EUV machines simultaneously without generating the debris that contaminates mirrors in traditional systems. This could result in cost reductions of up to three times compared to current EUV-LPP systems.

xLight's Breakthrough

xLight's system, based on energy-recovery linear accelerators (ERL), aims to provide a cost-effective and sustainable EUV light source. Unlike LPP systems, which are complex and energy-intensive, the FEL-based source promises higher EUV output, less power consumption, and no contamination of mirrors.

According to research from Japan's Tsukuba High Energy Accelerator Research Organization (KEK), the estimated cost of building and operating an EUV-FEL system is far lower than LPP systems. For instance, a 10 kW EUV-FEL source would cost around $400 million to build, with annual operating costs of about $40 million, which is roughly three times less expensive than an equivalent LPP system.

xLight's technology could transform the economics of semiconductor manufacturing. Gelsinger noted that the system's design could support up to 20 ASML EUV machines simultaneously, while reducing operational and capital expenses by three times. This reduction would represent a substantial leap in manufacturing efficiency.

Aiming for Compatibility with ASML Tools

xLight's goal is not to replace ASML's EUV tools but to develop an EUV light source that is compatible with ASML's existing lithography systems. By 2028, xLight intends to offer a light source that can be connected to ASML's machines, contributing to ongoing semiconductor production. However, it remains uncertain whether xLight's technology will be compatible with ASML's next-generation High-NA EUV systems, which are based on the LPP light source.

Despite the potential advantages of FEL technology, challenges remain, including the physical space required for the system and integration into existing cleanroom facilities. Nonetheless, if xLight's EUV-FEL system proves commercially viable, it may become a key component of the next generation of semiconductor manufacturing plants.

With its groundbreaking technology and ambitious timeline, xLight is positioning itself at the forefront of semiconductor innovation, aiming to help the U.S. reclaim and maintain its leadership in semiconductor manufacturing.

+86 191 9627 2716

+86 181 7379 0595

8:30 a.m. to 5:30 p.m., Monday to Friday