India’s Ministry of Electronics and Information Technology (MeitY) has approved the first batch of seven projects under the Electronics Component Manufacturing Scheme (ECMS), with a total investment exceeding INR 55.32 billion (USD 627 million / CNY 4.45 billion). The initiative marks a major step in India’s efforts to shift from assembling finished electronic products to manufacturing the modules, components, materials, and machinery that form their foundation.

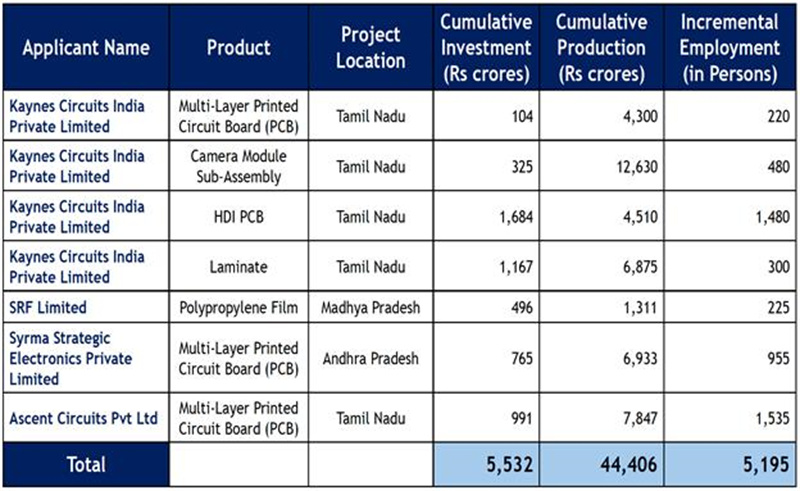

Announcing the approvals on October 27, Union Electronics and IT Minister Ashwini Vaishnaw said the new facilities will together generate INR 365.59 billion (USD 4.14 billion / CNY 29.43 billion) worth of electronic components and create over 5,100 direct jobs. The projects are distributed across Tamil Nadu (five units), Andhra Pradesh (one), and Madhya Pradesh (one), reinforcing India’s goal of balanced regional growth and expansion of high-tech manufacturing beyond major metropolitan areas.

Vaishnaw highlighted that the approved projects will significantly reduce India's import dependence and strengthen its position in the global electronics value chain. "Twenty percent of our domestic demand for printed circuit boards (PCBs) and 15% of camera module sub-assemblies will now be met locally," he said. "Copper Clad Laminate (CCL) demand will be met entirely through domestic production, with 60% of total output from these units to be exported."

Expanding India's Component Ecosystem

The seven approved projects include the establishment of new manufacturing units for High-Density Interconnect (HDI) PCBs, multi-layer PCBs, camera modules, copper clad laminates, and polypropylene films.

HDI and multi-layer PCBs form the core circuitry of smartphones, laptops, automotive systems, and industrial equipment.

Camera modules—compact imaging units used in consumer electronics, automotive systems, and medical instruments—will be produced locally for the first time.

Copper Clad Laminate (CCL), a base material used to manufacture multi-layer PCBs, will now be produced domestically, marking a strategic milestone in India's electronics material manufacturing capability.

Polypropylene films, essential for making capacitors used in electronics, telecommunications, automotive, and renewable energy applications, will also be produced in India under this scheme.

Building Trusted Supply Chains

According to MeitY, the ECMS is designed to create high-skill jobs, reduce import costs, and build trusted domestic supply chains across strategic sectors, including defence, telecommunications, electric vehicles (EVs), and renewable energy.

The initiative has drawn an overwhelming response from both domestic and global manufacturers. MeitY said it has received 249 applications representing proposed investments of INR 1.15 trillion (USD 13.0 billion / CNY 926.5 billion) and potential production output of INR 10.34 trillion (USD 117.2 billion / CNY 8.32 trillion) — the highest-ever investment commitment in India’s electronics sector.

The ECMS complements the Production-Linked Incentive (PLI) scheme and the India Semiconductor Mission (ISM), completing a seamless value chain from devices to chips, and from components to materials and innovation.

"India is transitioning from being a product assembly nation to a complete electronics manufacturing and design hub," Vaishnaw said. "These projects mark a crucial step toward that goal."

+86 191 9627 2716

+86 181 7379 0595

8:30 a.m. to 5:30 p.m., Monday to Friday