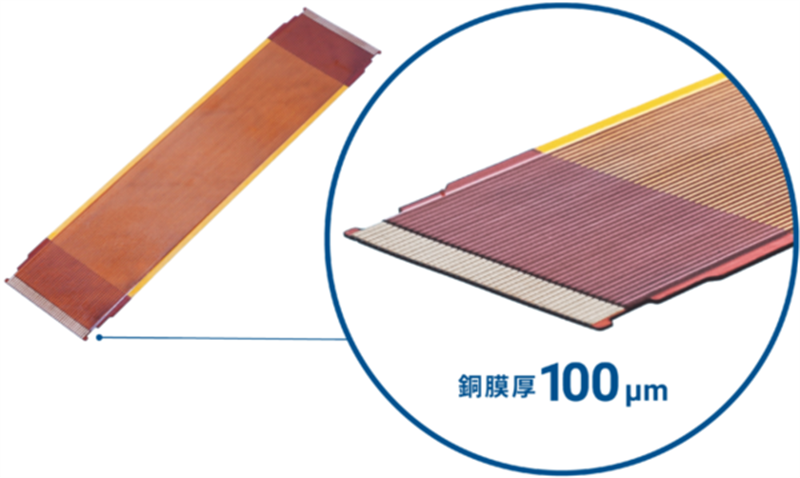

Japanese printed circuit board manufacturer Elephantech Inc. has officially announced the launch of mass production for two new types of flexible printed circuits (FPC) on April 9, 2025. The company will now produce thin-film FPCs with copper film thicknesses under 1μm and thick-film FPCs with copper film thicknesses exceeding 100μm. This expansion is part of Elephantech's ongoing efforts to extend the capabilities of its inkjet-printed circuit boards, branded SustainaCircuits.

Since 2020, Elephantech has been offering mass production of SustainaCircuits with copper film thicknesses ranging from 3μm to 12μm. However, responding to market demand for a broader range of products, the company has successfully developed new materials and processes to significantly expand this range. The new copper film thickness options will now cater to both ultra-thin and heavy-duty applications.

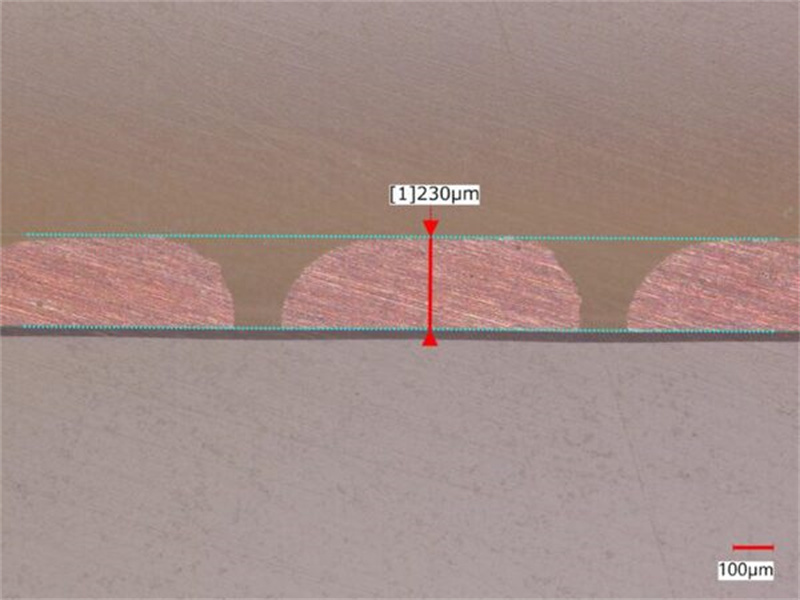

To achieve these advancements, Elephantech made developments on both the materials and process fronts. A key innovation includes the creation of a new primer that allows for higher adhesion strength while maintaining precise inkjet printability. The new primer has enabled the company to expand the range of copper film thicknesses, as well as to support polyimide substrates as thin as 12.5μm, a departure from the traditional 25μm thickness.

On the process side, Elephantech applied its proprietary electroplating technology, previously used in rigid multi-layer substrate development, to manufacture the thick-film FPCs. With this additive approach, copper is only deposited where needed, which contrasts with traditional subtractive methods that remove excess copper through etching. This additive method offers significant material savings and cost benefits, especially as copper thickness increases.

Currently, Elephantech is able to mass-produce copper films up to 100μm thick and is developing the capability to produce films up to 200μm thick. These thick-film FPCs are expected to be crucial for applications in the power electronics sector, such as automotive and industrial machinery, where high current handling is essential. The new FPCs could also replace traditional wiring harnesses, offering a more flexible and cost-effective solution for power distribution within vehicles and large industrial systems.

Elephantech's innovative copper film technology is already being explored for use in a variety of applications, including electric vehicle wiring, inverter systems, and battery interconnections, where the demand for higher current handling and flexible wiring solutions is growing. The company is also in discussions with several manufacturers about the mass adoption of these products.

+86 191 9627 2716

+86 181 7379 0595

8:30 a.m. to 5:30 p.m., Monday to Friday