On June 12, a research team from the University of Tokyo and AGC announced the development of a groundbreaking laser processing technology that increases glass substrate drilling speed by a factor of one million—an advancement expected to accelerate next-generation semiconductor and advanced packaging applications.

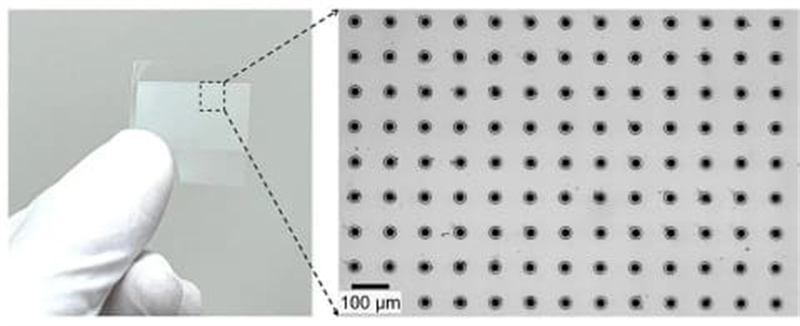

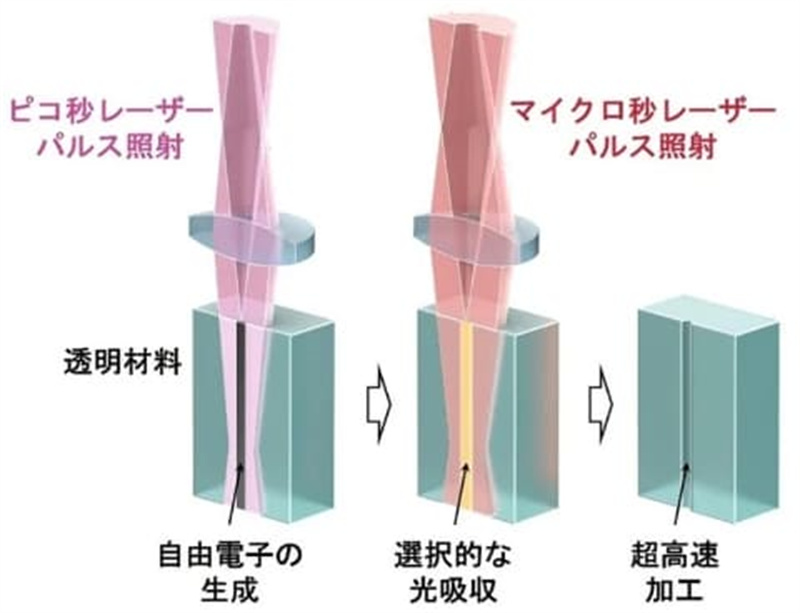

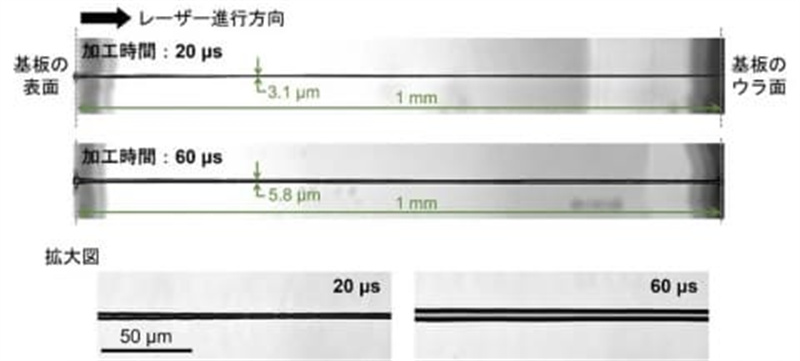

The technique uses ultra-fast laser pulses measured in picoseconds (one trillionth of a second) to temporarily alter the physical properties of glass, enabling highly efficient and precise drilling. The team successfully created ultra-high-aspect-ratio holes—1 mm deep and just 3 µm in diameter—in only 20 microseconds per hole, without causing cracks or shape distortion, common issues in conventional laser processing.

This breakthrough directly addresses a critical challenge in glass substrate fabrication. Since Intel's 2023 announcement to adopt glass substrates in future chips, global interest in glass microfabrication has surged. However, due to the brittle nature of glass, traditional chemical etching methods have proven slow and environmentally taxing, while conventional laser methods fall far short of the throughput required for practical semiconductor manufacturing—typically producing just one via in 10 seconds.

The new method solves this bottleneck by precisely controlling both the temporal and spatial waveforms of the laser beam. Remarkably, it also operates with laser power four orders of magnitude lower than femtosecond lasers, potentially reducing both equipment costs and energy consumption.

The process is compatible with a range of materials beyond glass—including sapphire, silicon carbide, and diamond—making it attractive for applications in aerospace, medical engineering, and advanced physics, in addition to semiconductors.

Industry experts note that this development could dramatically advance the commercial viability of glass substrates in high-density packaging, particularly for FC-BGA and AI server applications. It also introduces a new paradigm in materials processing—using momentary property modulation—to drive future innovations in precision manufacturing.

+86 191 9627 2716

+86 181 7379 0595

8:30 a.m. to 5:30 p.m., Monday to Friday